APPLICATIONS OF BOILER IN THE SEAFOOD INDUSTRY

Fish meal, originally an important source of animal protein, has become a popular product in the international market within the seafood industry. The fish meal processing primarily involves converting economically low-value fish into a high-protein feed through various stages, such as oil removal, drying, grinding, and other processing steps. In these stages, the use of fish meal production lines is indispensable.

Thăng Long’s fish meal production line is a top choice for the fish meal manufacturing industry, with the maximum thermal efficiency achievable being 98%. The fish meal production process commonly employs the wet processing method, which includes steps like chopping, cooking, pressing, separating, concentrating, drying, and grinding, etc. Here, the fish meal production line serves as an auxiliary equipment of this processing method. The demands for a fish meal production line in the fish meal manufacturing process are significantly high.

Selecting a high-quality fish meal production line can notably enhance the quality of the fish meal, extend the lifespan of the equipment, reduce maintenance costs, and increase profitability as well as return rates in a shorter time period. Simultaneously, with the enhanced global awareness regarding environmental protection, the demands for energy-saving and environmentally friendly equipment in the fish meal industry are gradually improving. Emission of exhaust gases and wastewater treatment must meet the relevant environmental requirements of the country.

Thăng Long Boiler specializes in providing custom design and installation services for new industrial fish meal production lines with high efficiency, environmental protection, energy savings, and reduced emissions, especially for fish meal plants, equipped with effective dust filters and sulfur removal devices, reducing the amount of pollutants emitted, and thoroughly addressing environmental pollution issues.

To learn more about the products and services of Thăng Long Boiler, please contact:

Address: 225 Phan Van Mang, KP9, TT. Ben Luc, Ben Luc district, Long An province

Contact: Mr. Nhan (0912 172 329) or Mr. Khai (0911 043 699)

Email: [email protected]

related products

related news

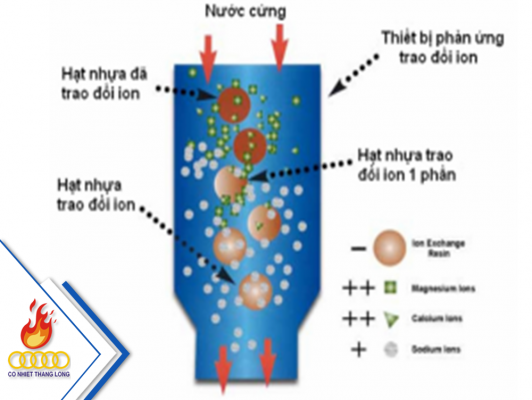

Table of water quality requirements

Water supplied to boilers usually comes from various sources, predominantly from municipal water in Industrial [...]

Is it necessary to treat boiler feed water

However, there are some misconceptions about boiler feedwater: Some people believe that water in a [...]

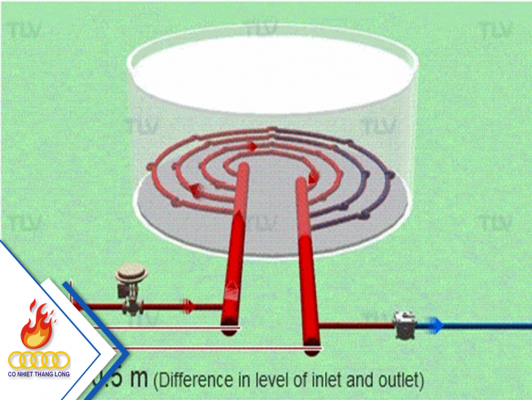

Water hammer in the device

What is the phenomenon of water hammer in equipment? The phenomenon of water hammer in [...]

Research on CO reduction

Source: Science and Technology Development Magazine: EARTH SCIENCE & ENVIRONMENTAL SCIENCES. VOLUME 2. NUMBER 1. [...]

Đỗ Thành Nhân

Director

Hotline: 0912 172 329

Email: thanhnhan.conhietthanglong@gmail.com

Consulting, project surveys, quotes, contracts.

Bùi Văn Khải

Vice Director

Hotline: 0911 043 699

Email: vankhai.conhietthanglong@gmail.com

Consulting, project surveys, quotes, contracts.

Contact Now

Thăng Long 24/7 support !

Error: Contact form not found.

Tiếng Việt

Tiếng Việt