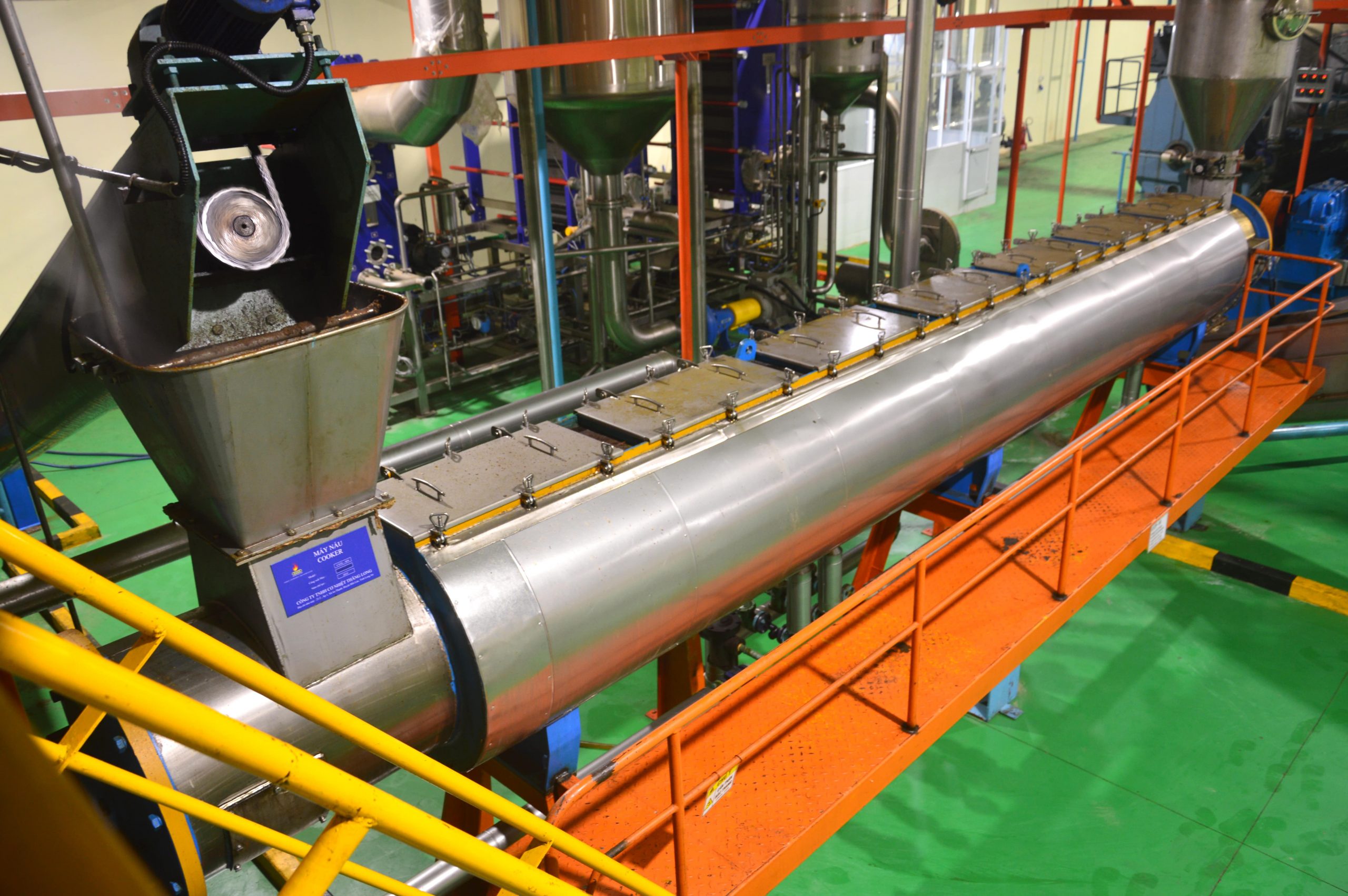

The oily fishmeal plant (the freshwater fishmeal processing line) adheres to strict requirements to ensure the production of high-quality fishmeal. Enormous, modern equipment facilitates rapid processing with large quantities.

The oily fishmeal plant

| 1 | Code | CNTL – BCN |

| 2 | Capacity | 80 – 300 tons of material / 24 hours (with juice evaporated in dryer) |

| 3 | Working pressure | 06 bar |

Contact Now

Thăng Long 24/7 support !

(Please contact or send request form to receive direct consultation from staff)

Specifications

| 1 | Code | CNTL – BCN |

| 2 | Capacity | 80 – 300 tons of material / 24 hours (with juice evaporated in dryer) |

| 3 | Materials |

Note: Large fish and fish by-products must be cut into small pieces by chopping machine |

| 4 | Working pressure | 06 bar |

Advantages

- Modern equipment and technology provide high efficiency at a low investment cost.

- The drying time is reduced while still ensuring the preservation of the nutritional content in the fishmeal.

Application

The oily fishmeal processing line is installed with a system that ensures adherence to the production process, preserving the nutritional ratio of the fishmeal. Freshwater fishmeal is used in the farming of poultry, carp, and the like.

Tiếng Việt

Tiếng Việt