BOILER APPLICATION IN RUBBER PROCESSING INDUSTRY

In the rubber processing industry, boilers play a crucial role by producing steam to supply vulcanization ovens and other processing steps. Vulcanization ovens are indispensable devices in transforming rubber from a liquid to a solid state and creating durable chemical bonds. In this article, let’s explore with Thang Long Boiler the applications of boilers in rubber processing.

The Importance of Boilers in the Rubber Processing Industry

Boilers are vital devices in the rubber processing industry. They play a role in generating the necessary steam for several crucial processes, including vulcanization, drying, adsorption, and bleaching. The significance of boilers in this sector is immeasurable because they provide high-quality temperature, pressure, and steam, enhancing the final product quality and optimizing the production process.

How Boilers Work in the Rubber Processing Industry

Boilers in the rubber processing industry operate by using fuel (such as coal, oil, gas, natural gas) to generate high temperatures, turning water into steam. The steam is then directed to processing steps like vulcanization, drying, adsorption, and bleaching. High-temperature and high-pressure steam enhances the vulcanization process and produces rubber with better durability and elasticity.

Advantages of Boilers in the Rubber Processing Industry

- Enhance production efficiency.

- Save energy and reduce costs.

- Meet safety and quality regulations.

- Minimize environmental impact.

Popular Types of Boilers in the Rubber Processing Industry

In the rubber processing sector, the most common type of boiler is coal-fired. However, various other types of boilers, such as oil-fired, gas-fired, and natural gas-fired, and more options, depending on the specific requirements of the production process.

Below are some considerations when choosing a boiler for the rubber industry:

- Select a boiler type compatible with the fuel used: Common fuels in the rubber industry include coal, oil, and gas. Each fuel type has its pros and cons. Therefore, select a boiler type that aligns with the fuel used to ensure efficiency and cost savings.

- Choose a boiler with adequate capacity: Boiler capacity should align with the factory’s production needs. An undersized boiler will not meet production requirements, leading to steam shortages, while an oversized one will waste energy and investment.

- Opt for a high-efficiency boiler: The higher the boiler’s efficiency, the more energy and cost savings.

- Choose an easy-to-operate and maintain boiler: Boilers should be easy to operate and maintain to reduce operational and maintenance costs.

- Select an environmentally friendly boiler: Opt for a boiler designed to minimize environmental pollution.

Thang Long Boiler is one of the leading boiler manufacturers in Vietnam, providing high-quality boilers for various industries, including the rubber processing sector. Thang Long Boiler’s products are designed and manufactured to meet the specific needs of the rubber processing industry, ensuring high, clean, and durable temperature and pressure. Thang Long Boiler’s products have been highly rated for their performance and reliability, aiding businesses in the rubber processing industry to optimize production processes and enhance product quality.

RELATED NEWS

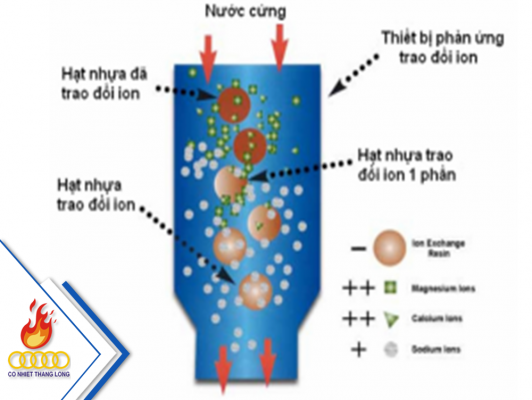

Table of water quality requirements

Water supplied to boilers usually comes from various sources, predominantly from municipal water in Industrial [...]

Is it necessary to treat boiler feed water

However, there are some misconceptions about boiler feedwater: Some people believe that water in a [...]

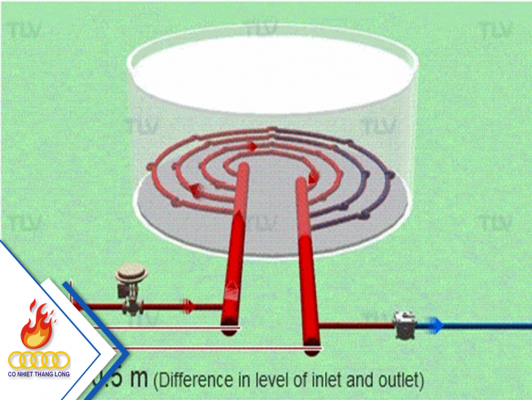

Water hammer in the device

What is the phenomenon of water hammer in equipment? The phenomenon of water hammer in [...]

Research on CO reduction

Source: Science and Technology Development Magazine: EARTH SCIENCE & ENVIRONMENTAL SCIENCES. VOLUME 2. NUMBER 1. [...]

Đỗ Thành Nhân

Director

Hotline: 0912 172 329

Email: thanhnhan.conhietthanglong@gmail.com

Consulting, project surveys, quotes, contracts.

Bùi Văn Khải

Vice Director

Hotline: 0911 043 699

Email: vankhai.conhietthanglong@gmail.com

Consulting, project surveys, quotes, contracts.

Contact Now

Thăng Long 24/7 support !

Error: Contact form not found.

Tiếng Việt

Tiếng Việt