BOILER APPLICATION IN FERTILIZER PRODUCTION INDUSTRY

Boilers are an indispensable factor in the fertilizer manufacturing industry, mainly due to their ability to provide the necessary temperature for production processes. Below are significant aspects of the importance of boilers in this sector

The Importance of Boilers in the Fertilizer Industry

Drying Raw Materials: In fertilizer production, raw materials often need to be dried to remove moisture. Boilers provide the high temperature necessary to carry out the drying process effectively, thereby increasing productivity and product quality.

Decomposition of Material: Some types of fertilizers are produced by decomposing organic matter. This process requires high temperatures to activate the reaction. Boilers ensure this temperature is available, contributing to efficient fertilizer production.

Nutrient Absorption: In some cases, heat from boilers is used to absorb nutrients into the fertilizer, improving its nutritional composition and value.

How boilers work in the fertilizer industry

Boiler Operation in the Fertilizer Industry Boilers in the fertilizer manufacturing industry typically use fossil fuels such as coal, oil, or gas to generate the required heat. Water is boiled to create steam, which is then used to provide heat for the production processes. Below are common types of boilers used in the fertilizer industry:

Water Tube Boilers: This type of boiler uses water to transfer heat from the fuel to the devices that need heating. Water in the boiler is heated and pressurized to create steam.

Fire Tube Boilers: This boiler type uses fuel to heat water tubes, and then the water is used to provide heat. This type is often more efficient because it does not need to transfer heat through water.

Advantages of Boilers in the Fertilizer Industry Boilers

Increased Productivity: Boilers help increase production efficiency by shortening the drying and decomposing time, thereby enhancing production efficacy.

Improved Product Quality: Boilers improve the quality of fertilizer products by eliminating moisture and impurities, ensuring the products meet quality standards.

Cost Reduction: Boilers help reduce fertilizer production costs by saving energy and optimizing production processes.

Flexibility: Boilers can be used to provide heat for various production processes, making plants more versatile in producing different types of fertilizers.

Important Factors When Choosing Boilers for the Fertilizer Industry

Important Factors When Choosing Boilers for the Fertilizer Industry When selecting a boiler for the fertilizer manufacturing industry, consider the following factors:

Capacity: The boiler’s capacity must be sufficient to meet the heat demand of the production processes. Accurate capacity calculation is crucial.

Boiler Type: It’s vital to determine whether water tube or fire tube boilers are suitable for the specific needs of the plant.

Fuel: Fuel choice must be based on the economic and environmental conditions of the plant. Balance the fuel’s efficiency and cleanliness.

Quality: Choose boilers from reputable suppliers to ensure quality and safety. Reviewing choices from credible suppliers is important.

Considerations for Boiler Use in the Fertilizer Industry To ensure efficient and safe boiler operation, regular maintenance and servicing are required. Maintenance and servicing tasks typically include:

Inspecting and cleaning boiler parts. Checking and replacing worn or damaged parts. Examining and adjusting safety devices to ensure proper operation. Boilers play an irreplaceable role in the fertilizer manufacturing industry, optimizing production processes, improving product quality, and reducing production costs. However, the selection, use, and maintenance of boilers need to be performed carefully and in compliance with environmental regulations to ensure safety and environmental protection.

related products

related news

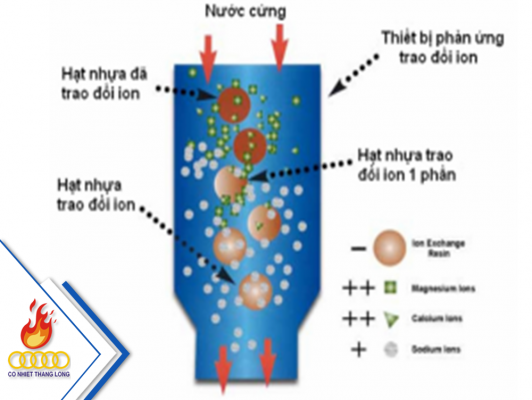

Table of water quality requirements

Water supplied to boilers usually comes from various sources, predominantly from municipal water in Industrial [...]

Is it necessary to treat boiler feed water

However, there are some misconceptions about boiler feedwater: Some people believe that water in a [...]

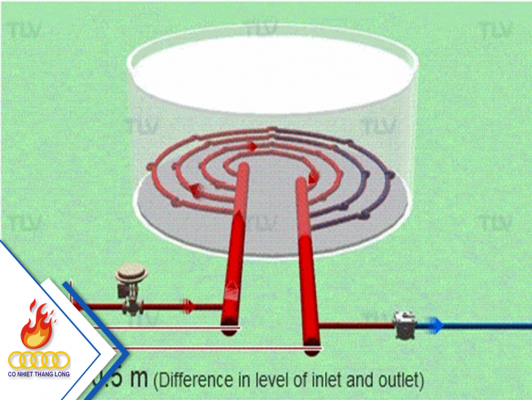

Water hammer in the device

What is the phenomenon of water hammer in equipment? The phenomenon of water hammer in [...]

Research on CO reduction

Source: Science and Technology Development Magazine: EARTH SCIENCE & ENVIRONMENTAL SCIENCES. VOLUME 2. NUMBER 1. [...]

Đỗ Thành Nhân

Director

Hotline: 0912 172 329

Email: thanhnhan.conhietthanglong@gmail.com

Consulting, project surveys, quotes, contracts.

Bùi Văn Khải

Vice Director

Hotline: 0911 043 699

Email: vankhai.conhietthanglong@gmail.com

Consulting, project surveys, quotes, contracts.

Contact Now

Thăng Long 24/7 support !

Error: Contact form not found.

Tiếng Việt

Tiếng Việt