BOILER APPLICATIONS IN THE GARMENT INDUSTRY

Boilers play an undeniable role in the textile industry, especially in the sludge cooking process at weaving factories and the dyeing, heating, and fabric drying processes at other plants. In the past, these processes were often performed laboriously and manually, but today, boilers have brought convenience and efficiency, saving both labor and time, and providing higher performance than traditional processes.

The steam generated from boilers not only affects the quality of dyeing and drying products but also affects the fuel and operating costs of the plant. Therefore, choosing an appropriate boiler, especially in the context where global textile factories are facing various possibilities and challenges, becomes extremely crucial.

In many developing countries, the choice of boilers is based on a consideration between fuel costs and environmental regulations. While coal and biomass-fired boilers have a cost advantage, gas boilers, although more expensive in fuel costs, bring benefits in automation and flexibility in operation and installation.

Currently, there are popular types of industrial boilers chosen by many garment factories or enterprises:

- Chain grate boilers.

- Husk fired boilers.

- Gas and biogas boilers.

Advantages of Boilers in the Textile Industry

Complete Combustion: Boilers can fully burn fabric scraps, leaving no black liquid on the steam tubes, and emitting no black smoke, ensuring clean operation and environmental safety.

Energy Saving: No need to use additional electricity or fuel during burning, helping to save energy and reduce operating costs.

Reasonable Investment: The investment cost in boilers is considered appropriate and reasonable, facilitating investment and development.

Waste Elimination: Boilers can destroy fabric scraps and various industrial waste that the textile manufacturing industry generates, contributing to reducing environmental pollution.

Emission Standards Compliant: Emissions from boilers meet quality standards and have low concentrations, ensuring compliance with Vietnam’s environmental norms and standards.

These features and advantages not only enhance efficiency and minimize environmental impact but also significantly improve management and operation for factories in the textile industry.

Thang Long Boiler is one of the leading companies in the market, specializing in providing and installing boilers, trusted by many businesses. They not only design boilers with fast-loading structures, reducing installation time but also integrate advanced technologies to optimize burning performance and energy efficiency, simultaneously reducing costs and operating time for textile enterprises.

To learn more about the products and services of Thang Long Boiler, please contact:

Address: 225 Phan Van Mang, KP9, TT. Ben Luc, Ben Luc district, Long An province

Contact: Mr. Nhan (0912 172 329) or Mr. Khai (0911 043 699)

Email: infor@thanglongboiler.com

With expertise and many years of experience, Thang Long Boiler commits to providing efficient and economical boiler solutions for the textile industry.

RELATED NEWS

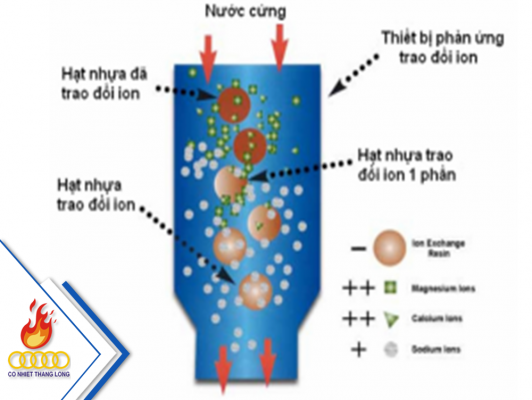

Table of water quality requirements

Water supplied to boilers usually comes from various sources, predominantly from municipal water in Industrial [...]

Is it necessary to treat boiler feed water

However, there are some misconceptions about boiler feedwater: Some people believe that water in a [...]

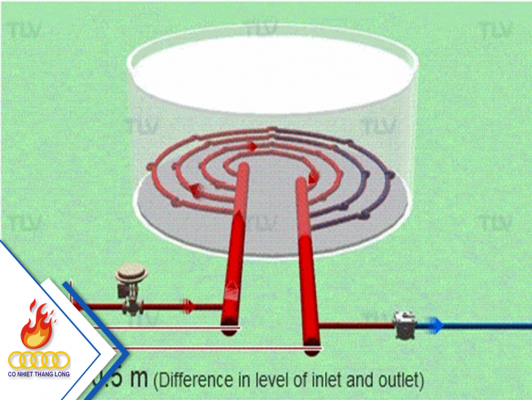

Water hammer in the device

What is the phenomenon of water hammer in equipment? The phenomenon of water hammer in [...]

Research on CO reduction

Source: Science and Technology Development Magazine: EARTH SCIENCE & ENVIRONMENTAL SCIENCES. VOLUME 2. NUMBER 1. [...]

Đỗ Thành Nhân

Director

Hotline: 0912 172 329

Email: thanhnhan.conhietthanglong@gmail.com

Consulting, project surveys, quotes, contracts.

Bùi Văn Khải

Vice Director

Hotline: 0911 043 699

Email: vankhai.conhietthanglong@gmail.com

Consulting, project surveys, quotes, contracts.

Contact Now

Thăng Long 24/7 support!

Error: Contact form not found.

Tiếng Việt

Tiếng Việt